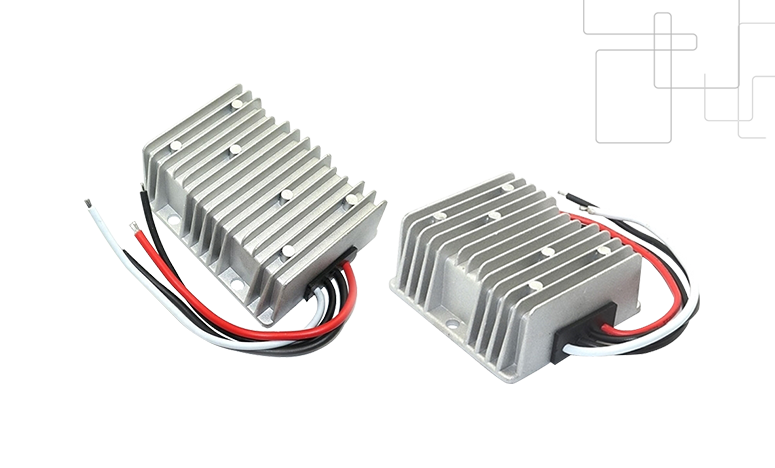

DC-DC Buck Converter Application in Industrial Automation

In modern industrial automation systems, power stability and efficiency are core elements for the long-term reliable operation of equipment. With the increasing number of sensors, controllers, communication modules, and actuators in industrial settings, power standards for different devices are often inconsistent. Therefore, power converters are necessary to adapt to the required voltage. DC-DC buck converters, with their advantages of simple structure, high efficiency, and stable output, occupy an irreplaceable position in the field of industrial automation.

I. Why Does Industrial Automation Need DC-DC Buck Converters?

The power supply voltage for most equipment in industrial settings comes from 24V DC, 48V DC, 72V DC, etc., while downstream equipment may require low-power logic power supplies or drive power supplies such as 5V, 12V, 15V. Directly using linear regulators not only results in low efficiency and high heat generation but also increases energy consumption and reduces system reliability. In comparison, DC-DC buck converters offer the following significant advantages:

- High energy efficiency: Buck converters typically achieve efficiencies of 85%–95%, far exceeding those of linear regulators, making them particularly suitable for battery-powered equipment or energy-sensitive industrial control systems.

- Stable output and strong anti-interference capability: Most industrial DC-DC modules feature short-circuit protection, over-temperature protection, and EMI control, ensuring stable operation of PLCs, sensors, and communication modules under complex operating conditions.

- Small size and easy integration: Buck converters can be integrated into various control boxes and equipment, significantly reducing space requirements and meeting the modular and compact design needs of automation equipment.

II. DC-DC Buck Converter Typical Applications in Industrial Automation

1. Sensor Power Supply (5V/12V/15V Regulated Output)

In industrial automation, numerous pressure sensors, level sensors, gas sensors, photoelectric sensors, and position encoders require stable power supplies. For example, the field bus may be 24V DC, but a level sensor only requires 12V. At this point, a DC-DC step-down converter can efficiently convert the voltage to the required voltage, making sensor measurements more stable and reducing noise.

2. Power Supply for Control Systems and PLC Modules

The internal circuits of PLCs and DCS control units often operate at 5V or 3.3V. In industrial environments with power fluctuations and high current surges, high-efficiency step-down converters can provide stable logic power, reduce power supply noise interference with control signals, reduce overall system heat generation, and improve reliability. Especially in scenarios where a large number of I/O modules are used in parallel, DC-DC converters become a critical basic component.

3. Industrial Communication Equipment (RS485, CAN, LoRa, EtherCAT)

Communication modules are typically extremely sensitive to power supply noise. In automated factories, communication networks include RS485 buses, CAN buses, Modbus, Ethernet switches, and wireless data acquisition devices. DC-DC step-down modules can ensure the voltage stability of communication chips, filter fluctuations from the bus, and prevent communication errors or data packet loss caused by power supply noise. This is crucial for the stable operation of smart factories.

4. Actuators and Drive Circuits

Servo motors, stepper motors, pneumatic solenoid valves, and relay modules often require different control voltage levels. For example, a solenoid valve coil requires 12V, the control signal requires 5V, and the drive board requires 15V. A single device may require multiple voltage levels; a step-down converter can generate multiple outputs under a single input condition, providing reliable power to the actuator.

5. Industrial Portable Devices and IoT Terminals

Industrial handheld instruments, wireless nodes, and mobile inspection devices are mostly powered by lithium batteries. DC-DC step-down converters step down lithium batteries (7.4V/11.1V) to 5V/3.3V to power microcontrollers and sensors, improving battery life, reducing heat generation, and facilitating handheld use. These products include portable gas detectors, vibration data loggers, handheld rangefinders, and data loggers.

III. Industrial-Grade DC-DC Buck Converter Technical Features

- Wide Input Range: Industrial applications often utilize a 4:1 or 2:1 wide voltage input, such as 9–36V and 18–72V, compatible with unstable power supplies or battery applications.

- Comprehensive Protection Functions: Includes input undervoltage protection, output overvoltage protection, output short-circuit protection, and thermal shutdown protection, ensuring safe operation even under harsh conditions.

- Excellent EMI/EMC Performance: Industrial environments are highly susceptible to interference; most modules meet EN55032 (electromagnetic compatibility), CISPR32, and industrial level 4 immunity standards, facilitating CE/UL certification.

- High Reliability and Long Lifespan: Industrial-grade DC-DC modules have a lifespan exceeding 100,000 hours (MTBF), making them suitable as a core power supply for long-term operation.

IV. DC-DC Buck Converters in the Automation Industry Future Trends

With the accelerated integration of industrial automation and the Internet of Things (IoT), buck converters are showing the following development trends:

- Higher efficiency (>95%)

- Miniaturization and high power density

- Increased integration (power supply + protection + communication functions)

- Active application of digital power control technology

- Wider input range and stronger anti-interference capability

These characteristics will drive their wider application in smart factories, robotics, smart energy, and other fields.

V. Conclusion

DC-DC buck converters are one of the most fundamental and critical power solutions in industrial automation systems. From sensors to controllers, from communication modules to actuators, almost all automated equipment relies on a stable low-voltage power supply. As the intelligence level of industrial equipment continues to increase, the demand for buck converters in terms of high efficiency, electromagnetic compatibility, and miniaturization will continue to grow, and their application prospects are very broad.